CERAMIC EQUIPMENT DESIGN

PLANT PICTURES

CLEANING

PLANT KEY DATA

RELATED VIDEOS

> High-flow Backwash

> Enhanced cake layer

removal using Sprinkler

> Air-scouring

(only during backwash)

> Sprinkler CapClean for

chemical cleaning

> Location: Caspian Sea

> Replacement of existing

lamella settlers by

integration of SiC

membranes

> Start-up 11/2017

> Feed COD/BOD/TSS

up to 120/30/117 ppm

> Feed turbidity up to

36 NTU

> TDS up to 2,000 ppm

> Up to 14,400 m³/d

> Filtered water SDI <1.0

NTU < 0.2/Fe < 0.02 ppm

MORE ABOUT

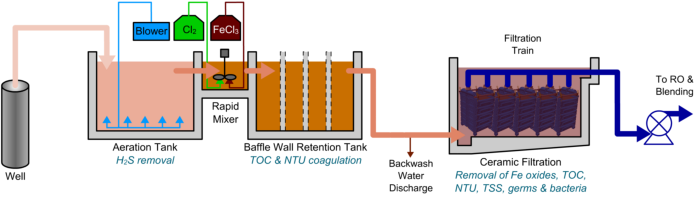

PROCESS FLOW DIAGRAM

Filtration Train Design

> Existing lamella settler basin split into 4 filtration Trains

> 2x5 module towers per Train (40 towers in total)

> Each tower equipped with 7 filtration modules

> Train design flux 357 - 476 LMH

> Max. flux 667 LMH (tested during pilot phase)

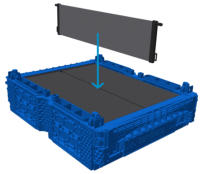

Filtration Module 6.0 S (from CERAFILTEC)

> Single Plates Water Collector design with 34 SiC

membranes (from Cembrane)

> Complete housing and piping equipment made in plastic

Source: Cembrane

cembrane.com

All About Ceramic Flat Membranes

Last update: 12/2017

© 2015

Source: Cembrane

cembrane.com

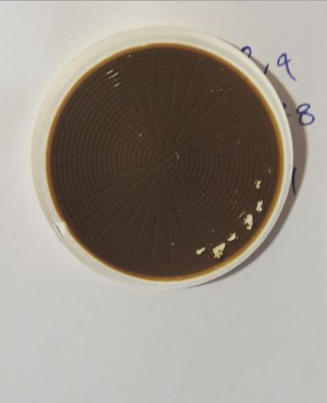

> Feed water to SiC membrane Train

SDI > 5 and Turbidity > 30 NTU

> Filtered water to RO

SDI = 0.20

> Filtered water to RO

Turbidity = 0.15 NTU

After 12 hrs dead-end filtration

and before backwash

After backwash with sprinkler

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com

Source: CERAFILTEC

cerafiltec.com