CERAMIC EQUIPMENT DESIGN OF ITN WATER FILTRATION

PLANT PICTURES

CLEANING

PLANT KEY DATA

RELATED VIDEOS

> High-flow Backwash

> Enhanced cake layer

removal using Sprinkler

during Backwash

> Air-scouring

(only during Backwash)

> CIP circulation with acid

mixture

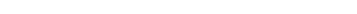

> Location: Middle East

> Start-up 05/2014

> Implementation of

HMO shock dosage

> 1st Ceramic train

replacement in 01/2016

> Up to 57,600 m³/d

> SDI < 1.0/NTU < 0.2

> Fe/Mn < 0.02/0.02 ppm

> Ra < 5.0 pCi/L

(up to 98% total removal)

> Recovery rate 99.2%

MORE ABOUT

PROCESS FLOW DIAGRAM

Filtration Train Design

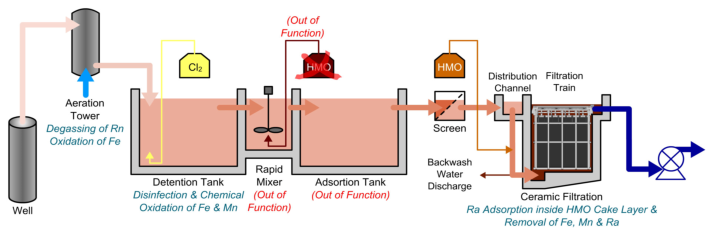

> Installation into existing 5 concrete basins

> 4 Filtration Racks per Train (20 Racks in total)

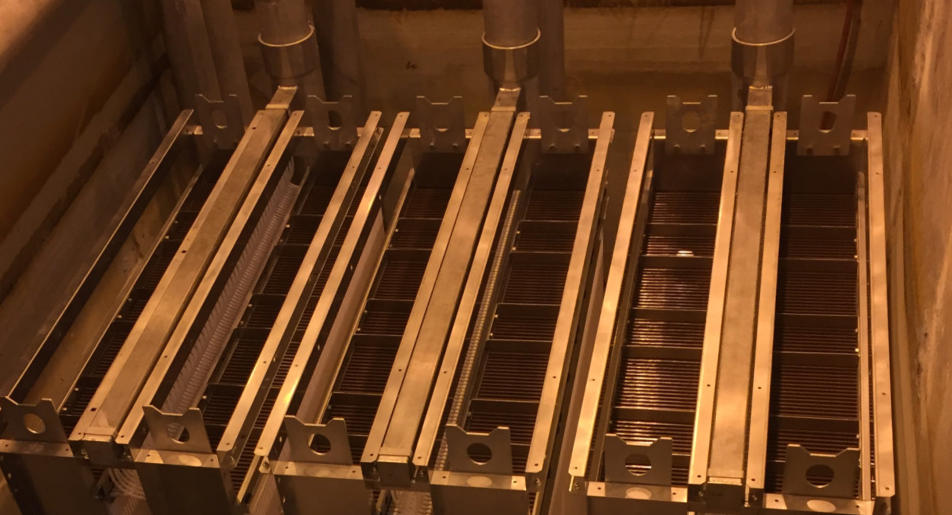

Filtration Module T-Series

> Multi Plate Water Collector with single component

complete membrane potting and internal module

piping connections

Filtration Rack T-Series

> Frame size and header connection suitable for direct

replacement of polymer membrane systems

> SS 316L frame with internal filtered water lines

All About Ceramic Flat Membranes

Last update: 12/2017

© 2015

CERAMIC EQUIPMENT DESIGN OF MEIDEN

CLEANING

> High-flow Backwash

> Air-scouring

(only during Backwash)

> CIP circulation with acid

mixture

MORE ABOUT

Source: Meiden

meidensha.co.jp

Filtration Unit CH250-1000TM100-U2DJ

> Double stack with 400 Single Plates

> Frame size and header connection suitable for direct

replacement of polymer or ceramic membrane systems

> SS 316L frame

Filtration Module CH250-1000 Series

> Single Plate Water Collector with external module

pipe & hose connections

Source: Meiden

meidensha.co.jp

Filtration Train Design

> Installation into existing Train 6 (replacement of existing

Ceramic Flat Membrane system)

> 5 Filtration Units per Train (5 Units in total)

Source: Meiden

meidensha.co.jp

Source: Meiden

meidensha.co.jp

Source: Meiden

meidensha.co.jp

Source: Published poster

Exhibition SWPF 2015

Source: Published poster

Exhibition SWPF 2013