MATERIAL

GENERAL PRODUCT STRUCTURE

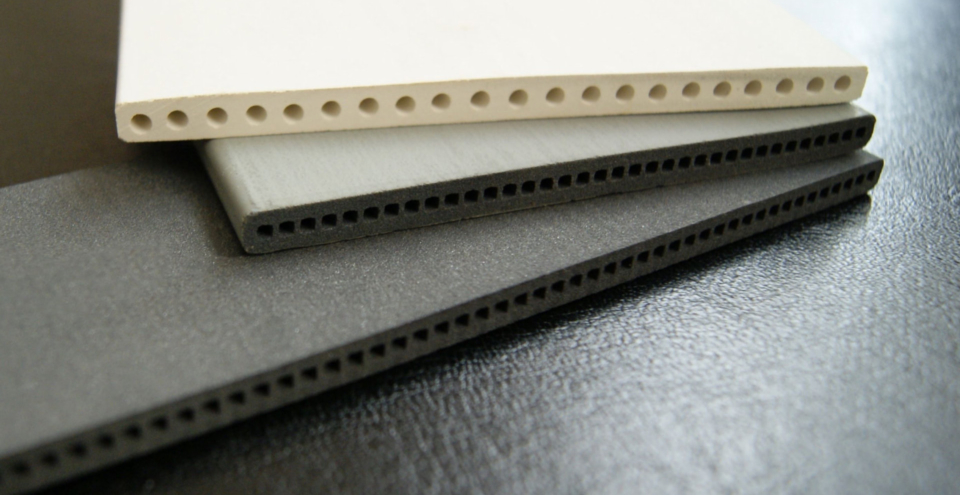

CERAMIC PLATE

KEY FACTS

> Inorganic filter material

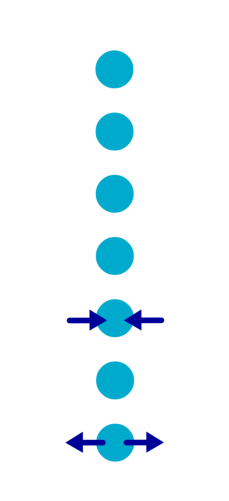

> Out-to-In filtration and In-to-Out backwash

> Submerged system

> Vaccum driven operation (negative transmembrane pressure TMP)

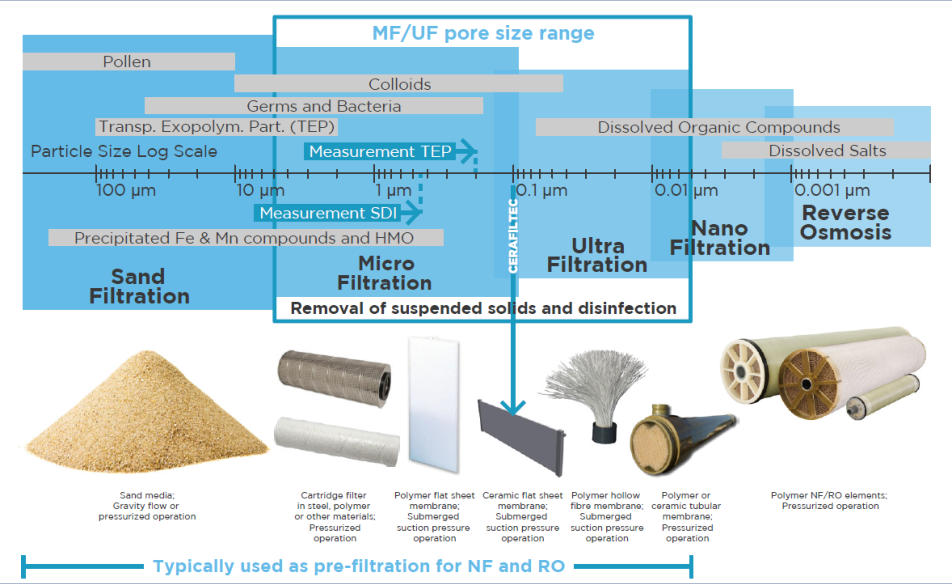

> Pore sizes typically in range of Micro & Ultra filtration 0.1 - 1.0 µm

> Due to very robust material suitable for challenging processes and applications

FILTRATION CLASSIFICATION

Ceramic

body

Filtered

water

channel

Filter active

layer with

defined

pore size

Out-to-In

Filtration

flow

In-to-Out

Backwash

flow

DIMENSION

CHANNEL DESIGN

> Length [mm] 300 - 1,200

> Width [mm] 50 - 800

> Thickness [mm] 4.0 - 8.0

> Circular

> Quadratic

> Elongated hole

> Rectangular

> Hexagonal

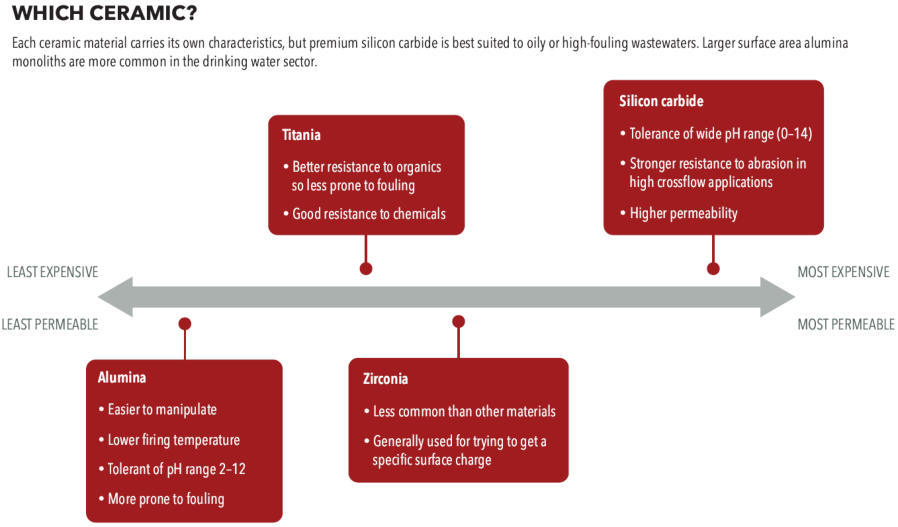

> Aluminia

Al2O3

> Silicon Carbide

SiC

> Titania

TiO2

> Zirconia

ZrO2

> Mixed Oxides

Al2O3/ZrO2/

TiO2/SiC

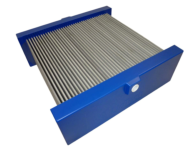

> Single Ceramic Plates

> Filtration Module

> Filtration Tower

> Ceramic front sides connected

with water collector

> Designed as Single Plate Water

Collector for one Ceramic plate or

Multi Plate Water Collector for

2 or more plates

> Several modules assembled

together and connected with

required piping and hoses

> Ready unit to be installed in

filtration tank and to be connected

to filtration pump equipment

Source: Liqtech

liqtech.dk

Source: Meiden

meidensha.co.jp

Source: CERAFILTEC

cerafiltec.com

All About Ceramic Flat Membranes

Last update: 12/2017

© 2015

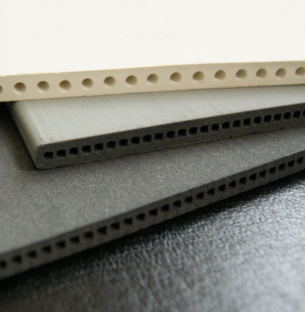

> Single plates in different materials,

dimensions and channel designs

Source: CERAFILTEC

cerafiltec.com

MATERIAL DIFFERENCES - GENERAL OVERVIEW

Source: GWI

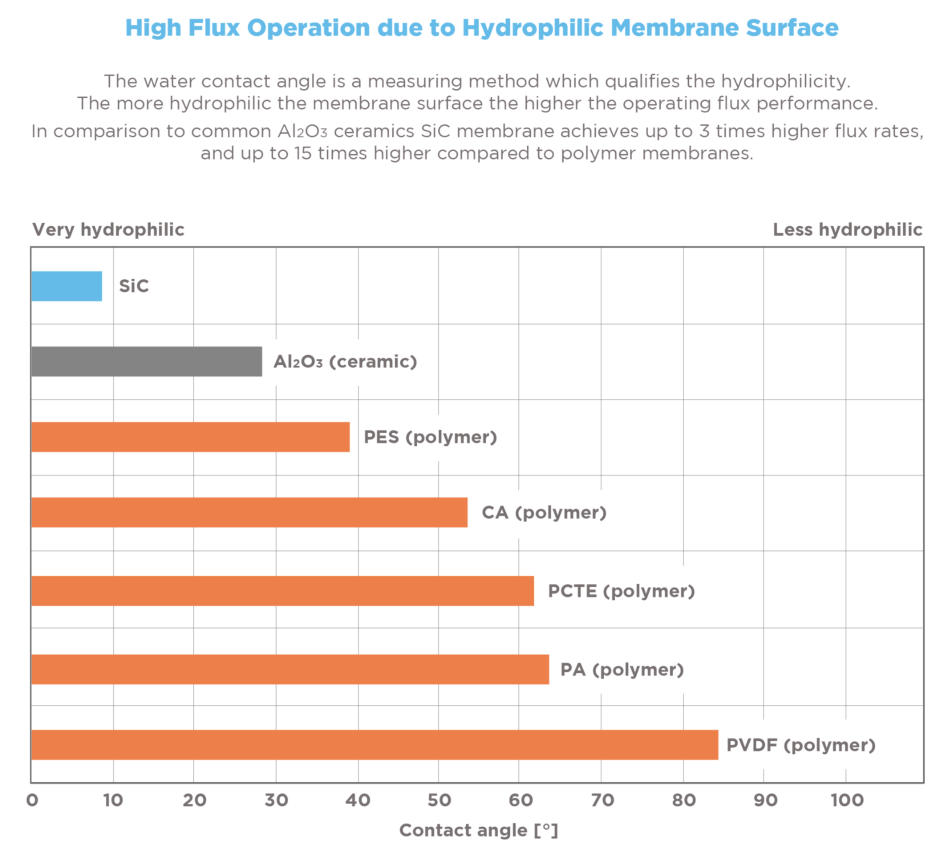

MATERIAL DIFFERENCES - FLUX PERFORMANCE

Source: GWI

Source: CERAFILTEC

cerafiltec.com

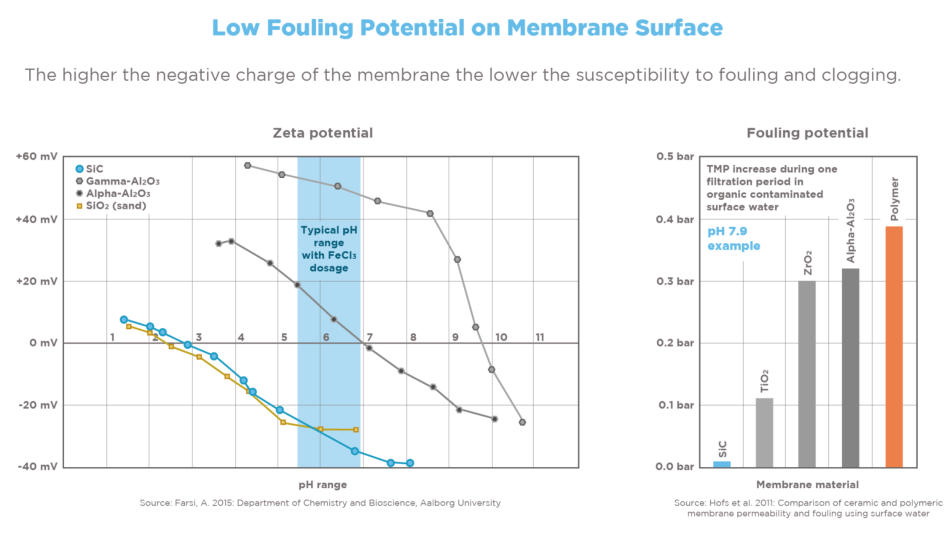

MATERIAL DIFFERENCES - MEMBRANE FOULING POTENTIAL

Source: CERAFILTEC

cerafiltec.com

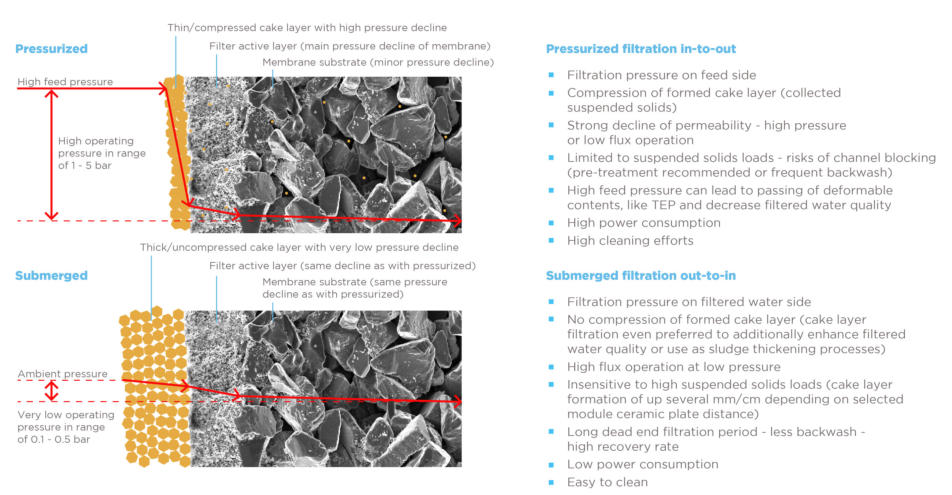

ADVANTAGES OF SUBMERGED OUT-TO-IN FILTRATION vs. IN-TO-OUT PRESSURIZED FILTRATION

Source: CERAFILTEC

cerafiltec.com