HISTORICAL HIGHLIGHTS

PRODUCTION

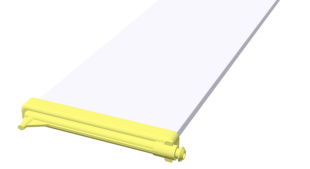

> Worldwide first full commercial

(large-scale) Al2O3 Ceramic Flat

Membrane production facility

> Capacity of up to 20,000 m²/year

> Location: Germany

> Former ItN Water Filtration

membrane producer until 2016

> Today Nanostone production

facility for its own segmented

ceramic membrane product

2003

PRODUCT LAUNCH

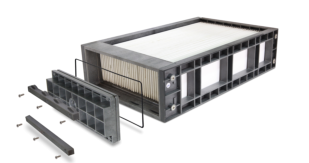

> Module with Al2O3 membranes

> Multi Plate Water Collector

> PVC Collector and Expoxy

ceramic gluing

> External module pipe connection

2004

PRODUCT LAUNCH

> Module with Al2O3 membranes

> Single Plate Water Collector

> PVC/PES/SS Collector and

Expoxy/PUR ceramic gluing

> External module pipe and hoses

2005

REFERENCE PLANT

> Worldwide first MBR using

Ceramic Flat Membranes

> Al2O3 membranes

> Location: Germany

PRODUCT LAUNCH

> Module with Al2O3 membranes

> Multi Plate Water Collector

> Partial membrane potting

> External module pipe connection

2006

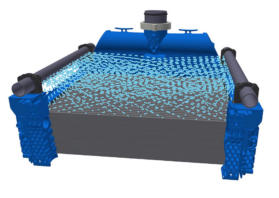

CLEANING PROCESS

> MCP

> Mechanical Cleaning Process

> Continuous membrane surface

cleaning using MBBR carrier

media

2007

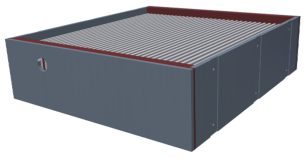

PRODUCT LAUNCH

> Module with Al2O3 membranes

> Multi Plate Water Collector

> Single-component complete

membrane PUR potting

> Internal module pipe connection

2008

CLEANING PROCESS

> Single nozzle line sprinkler

> Enhanced sludge and cake layer

removal process

2009

REFERENCE PLANT

> Worldwide first ground water

RO pre-treatment plant

> Al2O3 membranes

> Location: Saudi Arabia

2010

PRODUCT LAUNCH

> Module with Al2O3 membranes

> Single Plate Water Collector

> PVC Collector and ceramic gluing

> External module pipe and hoses

2011

2012

PRODUCT LAUNCH

> Module with SiC membranes

> Multi Plate Water Collector

> Single-component complete

membrane PUR potting

> External module pipe connection

2013

PRODUCT LAUNCH

> Module with Al2O3 membranes

> Multi Plate Water Collector

> ABS Collector and ceramic gluing

> External module pipe connection

REFERENCE PLANT

> First combined use of UASB

and Ceramic MBR for

industrial sewage treatment

> Al2O3 membranes

> Location: Singapore

2014

REMOVAL PROCESS

> Adsorptive Cake Layer Filtration

> Combined removal of dissolved

and suspended solids

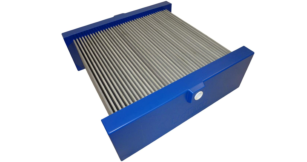

PRODUCT LAUNCH

> Module with SiC membranes

> Single Plate Water Collector

> GFRP Collector and

ceramic gluing

> External module pipe connection

2015

Photo: EDB Singapore

edb.gov.sg

Source: Published poster

Exhibition SWPF 2015

Source: Published poster

Exhibition SWPF 2015

Source: Published poster

Exhibition SWPF 2015

Source: Published poster

Exhibition SWPF 2015

Source: Meiden

meidensha.co.jp

Source: Liqtech

liqtech.dk

Source: Ceraflo

ceraflo.com

Source: Cembrane

cembrane.com

REFERENCE PLANT

> Worldwide first centralized

(larger-scale) Ceramic MBBR

> Al2O3 membranes

> Location: Saudi Arabia

PRODUCTION

> Worldwide largest Al2O3

Ceramic Flat Membrane

production facility

> Capacity of up to 180,000 m²/year

> Location: Japan

FILTRATION PROCESS

> Combined use of HMO

pre-treatment adsorption and

Ceramic Cake Layer Filtration

Source: Meiden

meidensha.co.jp

All About Ceramic Flat Membranes

Last update: 12/2017

© 2015

PRODUCTION

> First SiC Ceramic Flat Membrane

large-scale production facility

> Capacity of up to 30,000 m²/year

> Location: Denmark

Photo: Nanostone Water

nanostone.com

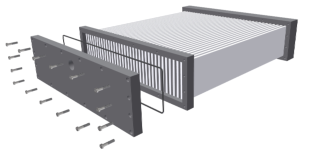

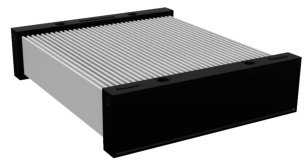

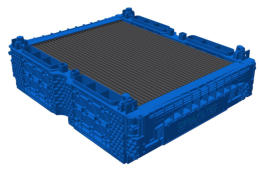

PRODUCT LAUNCH

> Module with SiC membranes

> Exchangeable single plates

> Fully made in injection molded

GFRP housing

> Internal module pipe connection

2016

TECHNOLOGY ALLIANCE

> Joined expertise of both

companies in ceramic production,

module production, engineering

design and future technology

developments

Source: CERAFILTEC

cerafiltec.com

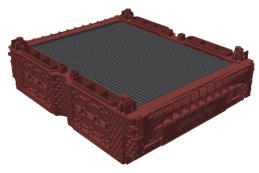

PRODUCT LAUNCH

> Module with SiC membranes

for hot water applications of up

to 99°C (boiling water)

Source: CERAFILTEC

cerafiltec.com

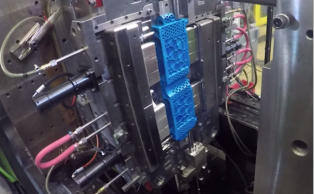

PRODUCTION

> GFRP module housing

> Fully automated injection molding

> Capacity of 75,000 modules

suitable for 450,000 m²/year SiC

membranes

> Location: Germany

2017

PRODUCTION EXPANSION

> Cembrane & CERAFILTEC agreed

for expansion of Cembrane’s SiC

production facility with own

CERAFILTEC production line

> Capacity of up to 140,000 m²/year

> Location: Denmark

Photo: CERAFILTEC

cerafiltec.com

Photo: Cembrane

cembrane.com

Photo Cembrane

cembrane.com

CLEANING PROCESS

> Double line sprinkler

> Improved cleaning option for

removal of thickened sludge and

formed cake layer

Source: CERAFILTEC

cerafiltec.com

FILTRATION PROCESS

> Flow Through Concept (FTC) for

MBRs

> Reduction of footprint of > 40%

> Lower risks of membrane surface

fouling and module tower clogging

> Improvement of flux rates of up

to 150 LMH

PRODUCTION

> Al2O3 membranes with ZrO2 layer

> New producer of ItN Water

Filtration (Safbon Water Service

subsidiary Jiangsu ItN Membrane

Filtration Technology)

> Capacity of up to 300,000 m²/year

> Location: China

Photo: Press release on

weixin.qq.com from 20. Nov. 2017

Source: CERAFILTEC

cerafiltec.com

Source: Ovivo

ovivowater.com

PRODUCT LAUNCH

> Module with SiC membranes

> Single Plate Water Collector

> Fully made in plastic

> External module pipe connection

NEW APPLICATION

> Removal of MnO2 particles in

Semiconductor factory

> SiC membranes

> Location: China

Photo: Cembrane

cembrane.com

NEW APPLICATION

> De-Watering Recovery System

> Municipal sewage excess sludge

thickening

> Dynamic shock removal process

> SiC membranes

> Location: Canada

Source: Purifics

purifics.com